Sewing needles for denim. Types of needles for sewing machines

A leather foot and needle are necessary if you want to sew clothes or accessories made of genuine leather or suede.

Foot and needle for leather: choose carefully!

There are special sewing machines for sewing leather, but with the help of a special foot and needle, even a simple seamstress can cope with thin leather and medium-density skins. Thick, non-bending belt leather, unfortunately, is too tough for a household machine.

The main problem when working with leather is that it does not move well when sewing and the stitches are very frequent. Therefore, a special “Teflon” foot is needed. You will immediately recognize it in a store window by its white color. This foot is made of special plastic and glides perfectly over leather or suede. It is produced by various manufacturers. Make sure the presser foot is suitable for your type of sewing machine: write down the manufacturer and model of the machine before going to the store. There is a foot and a needle for leather and for industrial machines.

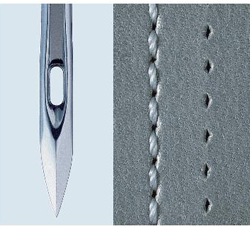

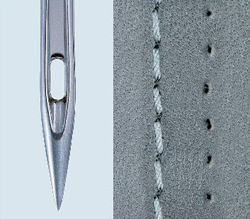

And don't forget about needles! Leather needles have a triangular shape and are trimmed with a spatula so as to cut through the skin rather than pierce it. This method does not leave additional microcracks on the skin, the seam looks neater and will last longer.

You also need to take not ordinary threads for sewing, but special ones - for leather, durable and elastic. If you plan to sew a lot of products, it will be cheaper and more convenient to immediately buy a large bobbin. At the beginning and end of the inner seam, be sure to tie a double knot and secure it with a drop of suitable transparent glue. Also tie a double knot on the outside, but then pull the ends of the threads through one of the holes in the adjacent stitch, bringing the needle out after 2-3 stitches. Pull the threads firmly - the tied knot should go inside the seam. Now the tails of the threads can be trimmed close to the stitching. And remember that the stitch length should not be too short! The optimal size is 3-5mm.

Foot and needle for leather: video instructions for installation and use.

Happy sewing!

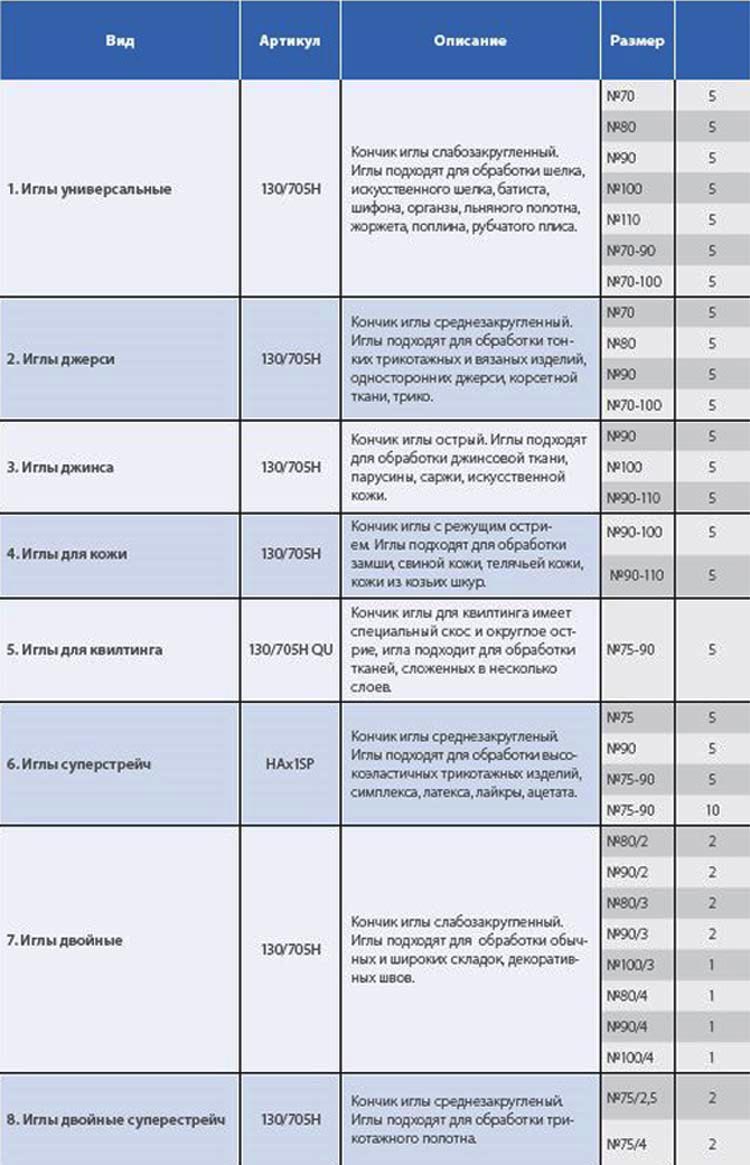

Needles for sewing machines They are divided into household and industrial and do not replace each other. This article will focus on needles for household sewing machines. They are not suitable for overlockers.

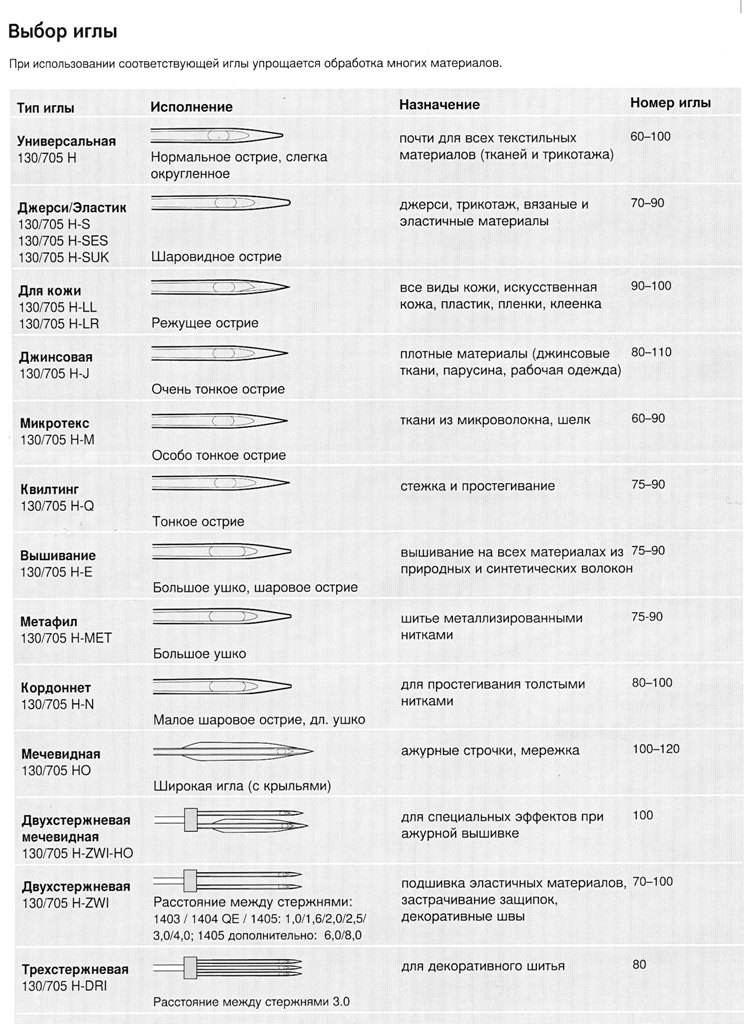

The range of needles is very large: different manufacturers, different purposes. Let's try to understand the avalanche of information using the example of Schmetz needles.

Table of ratio of thread number, needle number and fabric

Each needle is designed for a specific type and thickness of fabric. The thicker the fabric, the larger the needle number.

More detailed information on the relationship between needle and specific fabric in the forum topic

. This information can be downloaded by one.

Needles for household sewing machines

Needles for knitted and elastic fabrics

Needles for jeans

Needles for decorative work

Double and triple needles

Skin needles

|

|

Easy threading needle

Sewing needle installation

|

The thicker the fabric, the larger the needle number. When sewing stretch, denim, and silk fabrics, try to use the appropriate needle. Also remember to select the sewing thread according to the needle number and fabric you choose. Thin threads and needles are generally used for sewing thin fabrics, while thicker needles and threads are used for sewing heavier fabrics. The upper and lower threads should be the same if it is just sewing and not decor or embroidery. |

You can buy fabrics and accessories during the Season. The selection is unusually large - more than 6,000 items. The prices will pleasantly surprise you - they are lower than in a real store. By clicking on the preview with the sample you will be taken to the desired section of the store.

Nowadays, for leather products, in addition to durability, depending on fashion, in addition to strength, the appearance of the seam is decisive. In order to create a cost-effective production, seam placement occurs at high sewing speeds using modern machines. GROZ-BECKERT leather finishing needles produce beautiful seams in all areas of application.

- Product description

Groz-Beckert leather finishing needles - beautiful stitches in all areas of application.

Leather processing is one of the oldest craft arts. Nowadays, along with durability and strength, the appearance of the seam is of decisive importance, which changes depending on fashion. A strong connection should, if possible, also give the final product an attractive appearance. In order for the production of leather goods to be profitable, the seam is laid at high sewing speed on modern machines.

Customer needs include not only constant high product quality, but also production safety and minimal machine downtime. When developing the design and technology of the Groz-Beckert leather needle, the following requirements primarily played a role:

- Low needle breakage rate;

- Low stitch skip rate;

- Low thread break rate;

- High quality cut (clear and all layers);

- Long service life of the leather needle.

The result was the production of Groz-Beckert needles for processing leather goods with a cutting edge.

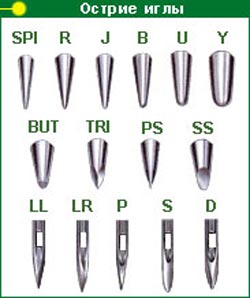

Depending on the type of leather and its treatment, the manufacturer recommends the use of the following types of needle points.

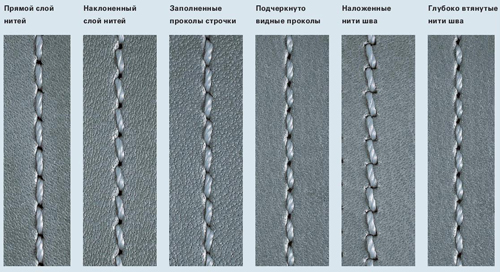

The appearance of the seam can also be changed using Groz-Beckert industrial sewing machine needles, depending on the design requirements of the finished product.

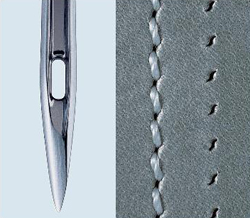

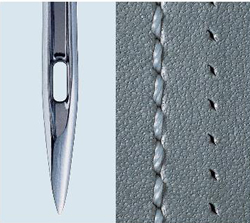

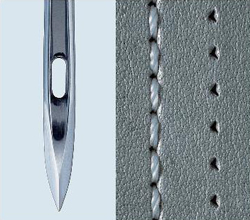

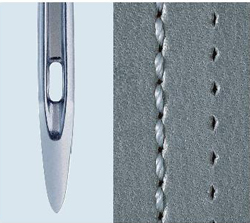

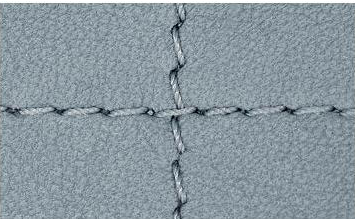

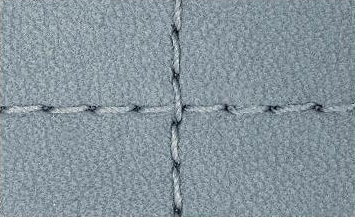

The following seam appearances below are shown with threading from left to right, and leather of medium thickness.

|

|

Needle point LR |

|

|

Needle point VR |

|

|

Needle point LL |

|

|

Needle point D |

|

|

DH needle point |

|

|

SD needle point |

|

|

Needle point P |

|

PCR needle point |

|

|

|

PCL needle point |

|

|

Needle point S |

|

|

DI needle point |

|

|

Needle point R |

Seam strength in leather products

A thread

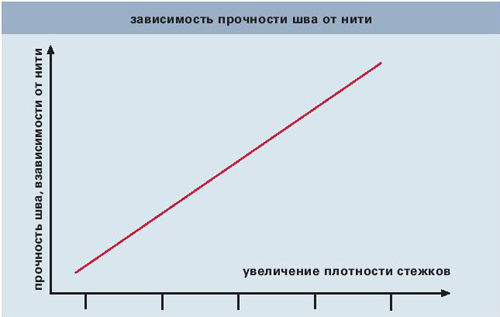

The higher the number of stitches (number of punctures per centimeter), the more thread is stitched. Thus, the seam strength associated with the thread increases with the number of stitches.

Leather

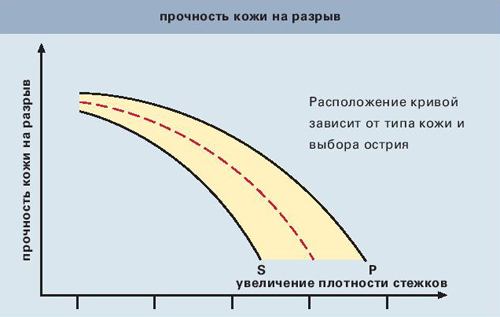

The greater the number of stitches and the thickness of the needle, the larger the cut in the skin.

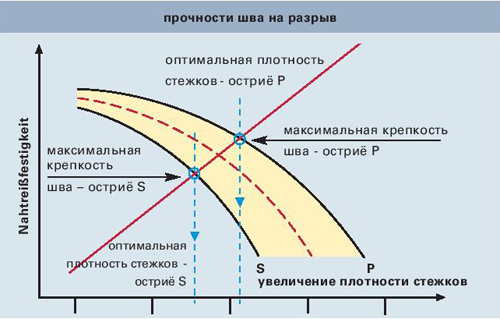

With the same needle thickness, the level of the cut and thus the level of strength depends, among other things, on the choice of point. Point P - gives maximum tensile strength because the cut occurs across the seam. The minimum tensile strength is provided by the S point, which cuts along the seam (standard stitch sewing machines). The curves of all other types of points are located between the P and S point curves.

In practice, maximum seam strength is achieved when both the leather and the thread are torn simultaneously when the seam breaks. In the graph, this is the intersection of the thread strength at the seam with the tensile strength of the leather, depending on the choice of point.

In order to obtain maximum seam density when changing the parameters: needle point or thread, the distance between stitches should be re-adjusted.

Sewing leather on two-needle machines

In one operation, two parallel seams are sewn simultaneously on two-needle machines. Ideally, the left and right seams should look the same. Due to the different mechanical principles of operation of the left and right needles, in most cases it is impossible to obtain an absolutely identical seam appearance.

Different loop technique

Seam shift due to twisting

Needle point R

LR Leather Needle Cutting Point

Leather Needle Cutting Point LL

The influence of skin on the appearance of the seam

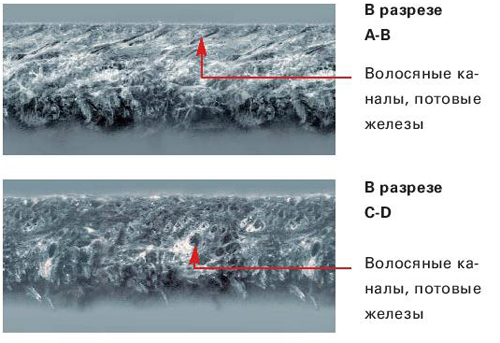

The skin has different longitudinal and transverse structures. The reason for this is the hair canals and sweat glands located along the material. Depending on this location, the appearance of the seam may differ.

![]()

The use of leather needles with a standard push point (eg R) can result in a significant difference in the appearance of the seam, depending on the direction of the seam and the type of skin.

To achieve an even stitching appearance, you must use leather needles with a cutting point.

If the seam must be straight in all directions, then cutting points S, LL, D or DH are recommended.

If a decorative seam is required on leather items with a slanted stitch appearance, then LR, VR or P cutting points are recommended.

Seam appearance: R point

Seam appearance: LL point

Seam appearance: LR point

Often, many sewing masters in the process of work more than once encounter quite common problems of skipping stitches or poor-quality stitching. Changing various settings of the sewing machine or alternating different types of stitches, as a rule, does not fundamentally change the situation for the better, and then everything is usually attributed to the poor quality of the equipment or the dishonesty of the manufacturer.

However, true professionals with the proper experience and qualifications are not always so categorical. They know one of the main secrets of sewing, which, in fact, is not a secret at all, but one of the fundamental foundations of this industry - the quality of the result directly depends on the correct selection of the needle.

Indeed, it is the needle installed in the sewing machine that will determine the smooth operation and quality of the result. Modern needles are distinguished by the widest variety - they can have different sharpening options, eye shapes, groove sizes, etc. All these features, some of which are practically invisible to the human eye, significantly affect the formation of the stitch, its integrity and quality.

Experts emphasize that whatever the parameters of the needle, it must fully correspond to the type and thickness of the fabric. Besides, modern technologies, used in light industry, are steadily leading to the emergence of new types of fabrics that have different properties and characteristics. When working with such fabrics, it is necessary to ensure the strength and quality of the thread connections, and at the same time not damage the structure of the fabric itself.

Typically, the correspondence between the types of needles and types of fabric is indicated in the instructions for sewing equipment. However, you should not rely entirely on this data - real professionals must have the knowledge and skills of interchangeability of needles, know their features and characteristics, since it is this knowledge that will help make the work easier in the future.

So, for example, you should approach the systematization of sewing needles with special care. The needle system can be individual for different machines, and when purchasing a needle, you need to know not only the type of machine for which it is intended, but also what the shape of the needle itself should be. For example, needles DBx1 and DPx5 - despite the fact that both are used for lockstitch machines, the bulbs of these two models are different. The type of needle can be found either in the instructions, or you can check it with the needles that the machine was originally equipped with. Also, some manufacturers indicate the type of needle directly on the machine body. Having bought a machine, you should immediately look and write down the type of needle, so that later you do not burden yourself with long and tedious searches.

How to choose the right needles for your home sewing machine?

In order to choose and buy the right needles for a sewing machine, you need to decide for what purposes they will be used and what types of fabrics they will work with. The needles have special markings that allow you to accurately identify their identity and the ability to interact with materials of various thicknesses.

Numbers on the markings of sewing machine needles

All household lockstitch sewing machines have been equipped with standard needles for many years. 130/705H. These are the numbers "130/705" mean to the average consumer that the needle is intended for a household sewing machine and has a flat flask.

For those new to sewing: it would be nice to know that there are also needles with round flasks, they are for industrial sewing machines.

Traditionally, needles from German companies are considered the best, in particular such as Schmetz, Organ Needles, Grotz-Beckert.

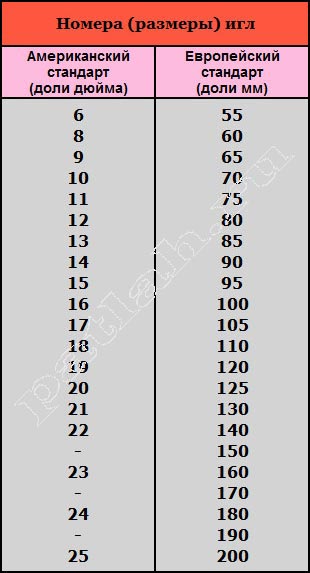

Table of sewing machine needle standards

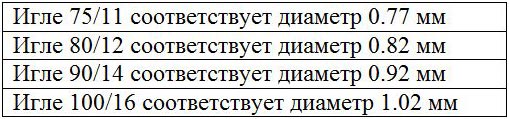

The number indicated in the name of the needle indicates its thickness (diameter) in hundredths of a millimeter or fractions of an inch. The higher the number with which the needle is marked, the thicker it is. Some manufacturers may indicate two values at once, for example 100/16 or 120/19. This means that the needle size is indicated in two units of measurement: millimeters and inches.

Approximate correspondence between needle diameters and fabric types:

- highly elastic knitted fabric, fabric with lycra and other elastic materials - needles No. 65-90;

- light fabrics for shirts, blouses - needles No. 60-70;

- thin fabrics (cambric, chiffon, crepe de Chine, etc.) - needles No. 80-90;

- linen, calico, chemical fiber and staple fabrics, materials for sewing suits - needles No. 80-90;

- light woolen fabrics and heavy ones made of chemical fibers, denim - needle No. 100;

- heavy woolen fabrics - needle No. 110;

- coarse cloth, beaver, burlap - needle No. 120;

- heavy and super-heavy materials (leather, tarpaulin, etc.) - for such materials, needles should be selected individually, since depending on the density, needle markings can vary from No. 100 to No. 200.

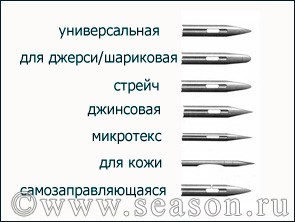

Needle applicability

In addition to the numbers in the marking of sewing needles, you can also find letter designations that determine the scope of application of each specific needle, i.e. what types of fabrics is it intended for?

The decoding of these values is as follows:

H - Universal needles- The needle point is slightly rounded, these needles are suitable for “not capricious” fabrics, linen, calico, cotton and others.

H-J(jeans) - Needles for thick fabrics- have a sharper edge, which makes them suitable for sewing thick materials - jeans, twill, tarpaulin, etc.

H-M(microtex) - Microtex needles- sharper and thinner. Such needles are used for precise piercing of microfiber, thin and densely woven materials, coated and uncoated raincoat fabrics, silk, taffeta, etc.

H-S(stretch) - Needles for elastic fabrics- these needles have a special edge that almost completely eliminates the possibility of missing stitches when the seam is stretched. The rounded tip pushes the fabric fibers apart without disturbing their structure. Used for sewing medium weight knitwear and synthetic elastic fabrics.

H-E(embroidery) - Embroidery needles- the eye hole in such needles is small, the point is slightly rounded. In addition, such needles have a special recess, which, in combination with other elements of the needle design, allows you to avoid damage to the material or threads. Designed for decorative embroidery with special embroidery threads.

H-EM - needles for embroidery or sewing with metallic threads. They have a large polished eye and groove to prevent delamination of metallized threads. Numbers 80 and 90. Number 80 needles for fine fabrics. No. 90 for thicker, heavier fabrics.

H-Q(quilting) - Quilting needles- these needles have a special bevel, a reduced eye and a rounded point to avoid skipping stitches and the appearance of puncture marks on the fabric. They are usually used in decorative stitches.

H-SUK(jersey) - Round point needles- easily moves apart the threads of fabric and loops and, due to this, passes between the threads, thereby eliminating damage to the material. Ideal for thick knits, jersey and knitted materials.

H-LR, H-LL(leder leather) - Leather needles with cutting point- the cut is made at an angle of 45 degrees to the direction of the seam. The result is a decorative seam, the stitches of which have a slight slope.

H-O - Needle with blade- designed for decorative finishing of seams, making hems using decorative stitches. Needles of this type have different blade widths. The blades can be on one side of the tip or on both. The use of these needles on lines where the needle punctures several times in the same place will enhance the decorative effect.

H-ZWI - Double needle- combines two needles united by one holder. The purpose of such a needle is decorative finishing and making tucks. Hemming the bottom of knitwear items (a zig-zag will form on the wrong side). The needles have only three sizes (No. 70,80,90) and three types (H, J, E). The distance between the needles is marked on the packaging in millimeters (1.6, 2.0, 2.5, 3.0, 4.0, 6.0). The higher the number, the wider the distance between the needles. Needles 4.0 and 6.0 can only be used on a straight stitch.

H-DRI - Triple needle- has only two sizes (2.5, 3.0). Working with this type of needle is similar to needles marked H-ZWI. When working with this type of needle, you should use stitches designed for use with a twin needle. If you select the wrong stitch, the needle may break and damage the machine or cause injury.

Topstitch - Special needles for decorative stitches- The needle has a large eye and a large groove so that the decorative thread (it is thicker than usual so that it is clearly visible on the fabric) easily passes through it. If you need to make a stitch with loose, disintegrating threads, then this needle will best choice. Numbers from 80 to 100. For light, medium and heavy fabrics.

This is shown more clearly in the table:

Parameters of needles for sewing machines.

1. Point of needles.

There are two main groups of points:

- needle point for textile group (has a round shape and sticks into the fabric);

- the point of a leather needle (has the shape of a blade and cuts through the fabric).

If the needle is chosen correctly, the stitching will look beautiful and there will be no damage to the material.

2. Eye of the needle

The smooth passage of thread through the eye at high sewing speeds is ensured by the streamlining of the needle eye and external shape. Due to the fact that the inner side of the eyelet is smooth, there is no weaving or breaking of the thread.

3. Groove (notch)

A good loop depends on the shape of the gutter. The previously used round groove is now mostly being replaced by a “Pontoon” groove, as this allows for better loop formation and prevents damage to the presser foot.

4. Needle shaft

Types of needle rods:

- shortened needle rods.

- doubly shortened needle rods.

The design of the needle rod determines the force with which the needle will pierce the fabric and its service life.

5. Needle flask

In a sewing machine, the needle holder has a certain size; if the size of the bulb does not match the size of the holder, then you will not be able to use the machine for its intended purpose.

There are round and flat flasks. Some systems have a round bulb with a recess to secure the needle.

Classification and applications of sewing needles

Needles with a cutting edge (for heavy materials, for leather products):

Needles with a pressed groove point (for straight quilting and blind stitches, for knitwear and other woven materials):

Needles for denim

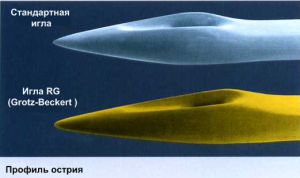

This type of sewing needle is one of the successful examples of the manufacturer’s attentive and responsible approach to product development. For sewing denim, needles marked RG are used. Although sewing needle The object itself is quite miniature; specialists managed to work out in detail all the smallest details in its design.

The needles in this series are produced using titanium-nitride coating, which in its physical properties surpasses the hardest alloys of steel and metals. Thanks to this, jeans needles have increased wear resistance and a very long service life.

Particular attention is paid to the shape of the needle tip - it is thinner than conventional needles, its end is slightly rounded. This shape, in combination with the mentioned titanium-nitride coating technology, gives an excellent result - damage to the material is almost completely eliminated and the likelihood of missing stitches is minimized.

Skipped stitches and needle breakage most often occur due to significant deviation of the needle when sewing intersections of seams. The needle developers took this point into account and modified the shape of the rod. Its conical shape, complemented by the cross-section of the groove, gives the needle a higher resistance to bending - from 20 to 40% compared to a standard needle.

Needles for leather goods

The needles from this series are another source of pride for the manufacturer. Specialists have managed to develop several modifications of needles with a cutting tip that allow them to work more effectively with various types of skin. Among the main advantages of needles for sewing leather are the low probability of needle breakage, the minimum level of stitch skipping and thread breakage, and the highest quality of the slot. Thanks to these features, sewing professionals can significantly increase productivity and use these needles for a long time with high intensity.

Needles for sewing on buttons

Most button sewing needles are equipped with an RG point. It was this form that was recognized by researchers as the most effective and practical to use. Thanks to the thin point, the needle passes freely into the hole of the button, thereby eliminating the possibility of damage. The same special shape of the needle allows you to significantly reduce the load on it - the resistance indicators of button needles are lower by an average of 40% compared to conventional needles. This allows you to protect the material, threads and the button itself from various negative influences, and also increases the service life of the needle itself.

Needles for technical materials

The key characteristics are similar to the previous ones - titanium-nitride coating is also used, the same RG tip is used, and when developing these needles, specialists also took into account many details of their subsequent use. These needles have a cross-section blade that provides higher needle stability and also have a reinforced tip for higher resistance. In addition, this type of needle is created with a deeper groove and a special eye shape, thereby minimizing the likelihood of thread breakage and skipped stitches.

Such design features needles provide consistently excellent results, which is especially important when working with technical materials that have not only an aesthetic, but also a functional purpose.

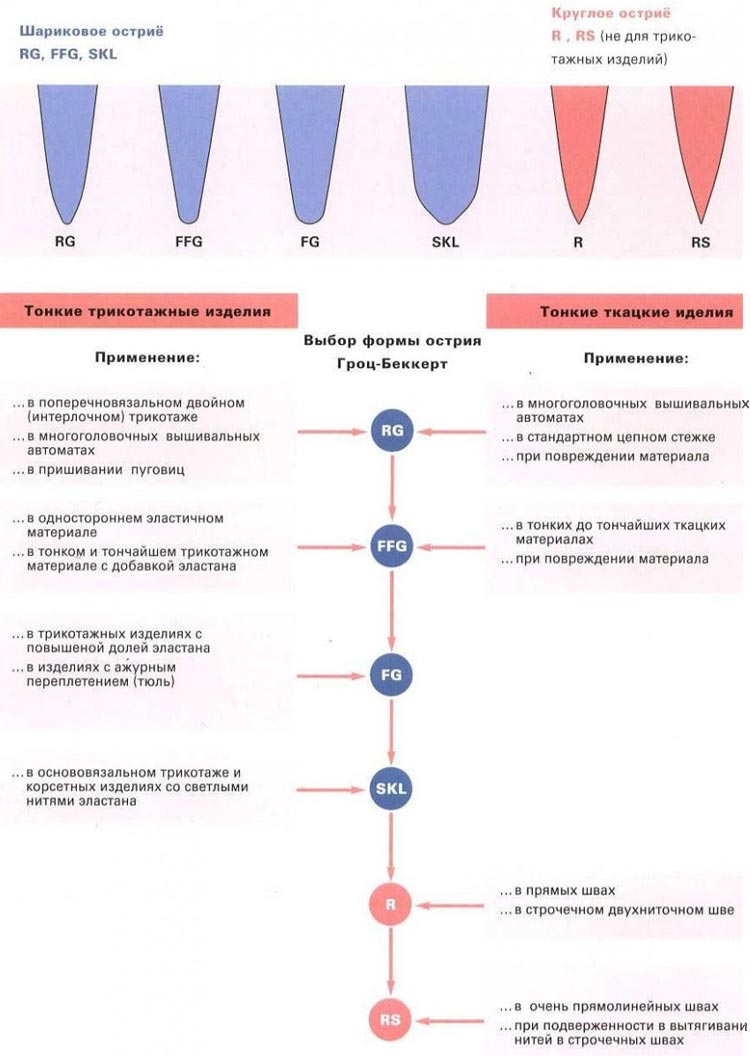

Needles for fine knitwear

Thin knitted materials are extremely popular nowadays. However, for their high-quality processing, sometimes it is necessary to comply with more stringent requirements than when working with other fabrics. This is largely due to the fact that when sewing clothes from thin materials, it is necessary to pay special attention not only to the beauty of the product, but also to the maximum possible wearing comfort. To ensure high-quality tailoring of such products, it is necessary to carefully monitor which needles are used when working with thin fabrics. For delicate materials there is a whole list of different needles.

Needles for sewing and embroidery

The needle point type for knitwear and textiles is standard. There may be no tip marking or an “R” designation. Used for: light fabrics, thin materials with or without coating, mass production of ready-made dresses from fur, leather and textile materials.

Small ball point “SES”- These needles easily move apart the threads of fabric, passing between them, eliminating damage to the material. Excellent for jersey and knit fabrics, but can also be used for: fine to medium knits, thin denim, multi-layer textile/textile fabrics.

Medium ball point “SUK”- Compared to “SES” the tip is more rounded. Perhaps this best view needles for working with denim fabrics such as “sand washed”, “stone washed” (especially when processing ready-made products and using large numbers of needles) and corsetry products (optimally when using thin needles). Ideal for medium to chunky knits, corsetry and denim fabrics.

Large ball point “SKF”- The more rounded shape of this type of needle allows the tip to push apart the threads of coarse knitwear and elastic materials without causing damage to them. It is best used when working with delicate elastic materials or elastomer wrapping threads, coarse knitwear.

Special ball point “SKL”- Provides targeted puncture of the fabric, which ensures better expansion of individual threads. It is the most suitable type for working with Lycra-type materials, but is also suitable for other elastic materials (from medium to coarse), including knitwear.

Thin rounded tip “SPI”- This type of needle provides precise piercing of densely woven and additionally coated materials. Used for microfacing, silk, coated materials, heavy woven fabrics such as canvas, smooth but heavy materials, as well as for processing shirt cuffs, collars and front panels. As a result of using such needles, a correct seam is obtained, without pulling or curls.

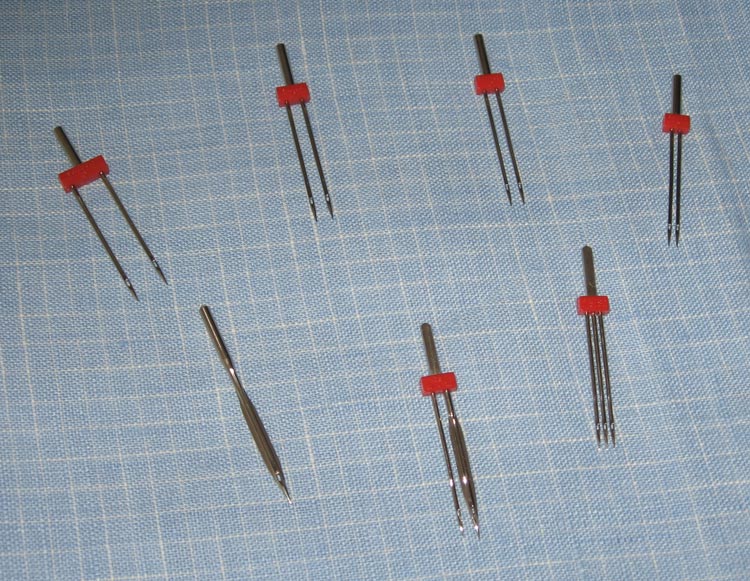

Double needle for sewing machine

A sewing double needle is indispensable when sewing clothes with double stitching. Finishing stitches on jeans, patch pockets, details on men's shirts, etc. You can stitch evenly and neatly by sewing the seam with a double needle.

How to use a double needle?

How to use a double needle? Just like with a regular needle, you just need to buy a suitable double needle for your sewing machine model and thread both upper threads simultaneously into two needles. Bottom thread in the bobbin will be used by both upper threads at the same time.

Twin needles will not fit all machines.

Twin needles can sew different fabrics, but only in machines with a zigzag stitch; straight-stitch machines like Podolsk are not intended for their use. The needle plate of these machines has one round hole, while the double needle requires a narrow and wide slot, which is used in zigzag stitch machines. In addition, thread guides for the second spool are also required.

The second spool needs a creel.

Modern sewing Janome machines, Brother, Juki and many others have a creel for two spools of thread and paired thread feeders and thread guides, into which the upper threads are threaded separately.

Installing a needle.

The double needle is installed in sewing machine, just like a regular needle. The flat of the needle (cut) should be directed back, away from you, and the round side should be directed towards you, forward. Each coil must have a separate pin (coil holder), sometimes an additional one is installed for this. If there is only one spool stand on the machine body, then a second one should be included in the kit. The threads from the spools are passed through all the thread guides, including the upper thread tensioner, together, and only the lowest thread guides separate them into needles. The left thread goes into the left needle, the right thread into the right. If there is only one thread guide, like Chaika’s, then the left thread is passed through the thread guide, and the right one next to it, directly into the eye of the right needle.

What types of needles are there and their purpose.

A double needle can have different distances between the needles - narrower, wider, and there are even triple needles. Different widths make it possible to choose the width of the finishing stitch and use it for design. The use of double needles is more intended for decorative seams that do not experience heavy loads.

Of course, it can be used to make finishing stitches on a pocket or flap shirt. But, we should not forget that to form a seam, a double needle uses only one lower thread, so such a seam will not be particularly strong. But, for example, for embroidering two or three parallel patterns at the same time, a double needle is simply irreplaceable. This pattern looks especially impressive if the threads are of different colors. Using double needles with a narrow gap between them, you can create an imitation of shadow in the design. Using narrow needles, I place threads on top of each other, creating a shadow effect. In addition to simple finishing stitches, double needles can be used for sewing on braid, performing elastic gathering, tucks and other operations.

Attention!

When buying double needles in a store for your sewing machine, pay attention to the maximum width of the needle plate opening on your machine, or simply the width of the zigzag stitch on your machine. Incorrectly selected needles may break, hitting the needle plate.

In addition, before you start sewing with a double needle, watch the stitch type switch. The stitch should not be set to a zigzag or other needle offset, such as zipper stitching, etc. The double needle should only work in straight stitch mode. In any other mode, they will simply break on the needle plate of the sewing machine.

- How to remove oxygen from water

- Drain fittings for toilet cistern

- Review of Roda air conditioners: mobile and wall-mounted models, their comparison, characteristics and instructions

- How to make your own passe-partout for children's work

- DIY crafts from leaves What composition can be made from leaves

- DIY home crafts: ideas for decoration and interior

- How to make topiary from artificial flowers and fruits

Live Journal

Live Journal Facebook

Facebook Twitter

Twitter LEDER LEATHER - for sewing leather. The needles differ from others in that they have a special groove on the needle shaft, a sharp knife-like point and a reinforced shaft.

LEDER LEATHER - for sewing leather. The needles differ from others in that they have a special groove on the needle shaft, a sharp knife-like point and a reinforced shaft.  Change the needle on time. Do not use a needle if it is bent, even “just a little,” or if it is jagged or has a dull point. Change needles every 10-12 hours of sewing or after two sewn items. Often the cause of thread breakage is a needle with a notch in the eye, as well as a needle that is incorrectly selected for the type of fabric.

Change the needle on time. Do not use a needle if it is bent, even “just a little,” or if it is jagged or has a dull point. Change needles every 10-12 hours of sewing or after two sewn items. Often the cause of thread breakage is a needle with a notch in the eye, as well as a needle that is incorrectly selected for the type of fabric.